Transforming Challenges into Opportunities

Transforming Challenges into Opportunities: A Forging Success Story in Oil and Gas

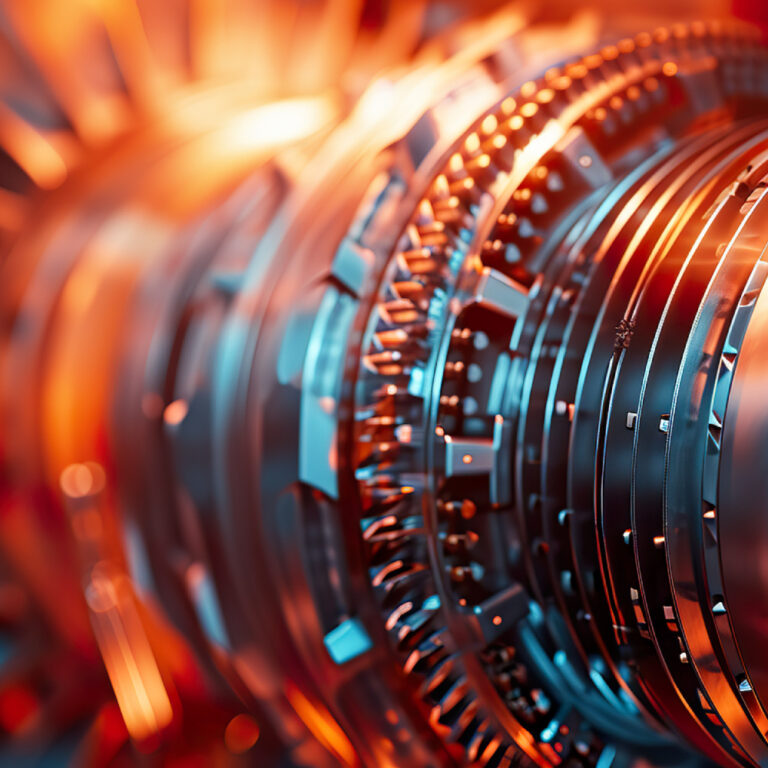

In the oil and gas industry, the demand for high-quality, durable components is paramount. Equipment and machinery operate under extreme conditions, facing high pressures, corrosive environments, and significant wear and tear. Custom forging emerges as a critical solution to meet these rigorous requirements. This success story illustrates how one such project transformed significant challenges into remarkable opportunities, benefiting both the client and the forging manufacturer.

Understanding the Challenge

The project began when a leading oil and gas company approached Manan Forge to develop a series of specialized components for a new offshore drilling platform. The client faced a significant challenge: existing suppliers were unable to meet the stringent specifications required for parts that could withstand harsh marine environments. These components needed to be resistant to corrosion, able to handle extreme pressures, and compatible with the latest technology. Additionally, the client required a rapid turnaround to meet their project timeline, which added to the urgency.

Collaboration and Innovation

Recognizing the importance of collaboration, Manan Forge assembled a dedicated team of engineers and production specialists to work closely with the client. The initial phase involved detailed discussions to fully understand the technical specifications, performance requirements, and operational constraints of the components. By fostering an open line of communication, the team was able to identify critical factors that would influence the design and manufacturing processes.

Innovative approaches were employed in material selection and process design. Manan Forge utilized advanced forging techniques and high-performance materials that offered enhanced strength and corrosion resistance. Furthermore, the team conducted simulations to predict the performance of the components under various operational scenarios, ensuring that they would meet or exceed the client’s expectations.

Overcoming Obstacles

As the project progressed, several unforeseen challenges arose. One of the primary obstacles was the need for precise tolerances, which posed risks during the forging process. Additionally, maintaining consistent quality across a high volume of components proved challenging. However, the team at Manan Forge leveraged their expertise in quality control and process optimization to address these issues.

Implementing stringent quality checks at each stage of production helped identify potential defects early, minimizing waste and ensuring that only the best components were delivered to the client. By investing in advanced testing facilities, Manan Forge was able to perform rigorous assessments on each component, ensuring compliance with industry standards.

Delivering Results

The culmination of these efforts resulted in the successful delivery of the components within the agreed timeframe. The client was not only impressed by the quality and performance of the products but also by the collaborative process that had driven the project. The components functioned seamlessly in the harsh offshore environment, contributing to the success of the drilling platform.

This project not only solidified the relationship between Manan Forge and the oil and gas company but also opened new avenues for future collaborations. The successful execution demonstrated Manan Forge’s capability to handle complex custom forging projects, positioning the company as a reliable partner in the oil and gas sector.

Conclusion

The journey of transforming challenges into opportunities in the oil and gas industry showcases the value of collaboration, innovation, and expertise in custom forging. By overcoming significant obstacles, Manan Forge not only met the immediate needs of the client but also reinforced its reputation as a leader in the industry. This success story serves as a testament to the importance of resilience and adaptability in manufacturing, highlighting how challenges can indeed lead to greater opportunities and advancements in technology and service.