Sustainable Engineering Design Practices

Sustainable Engineering Design Practices

Sustainable engineering design has become a critical focus in modern industries, driven by the need to minimize environmental impact while maintaining functionality, cost-efficiency, and performance. This approach goes beyond traditional design methods, integrating environmental considerations into every stage of the engineering process to create products, systems, and processes that are environmentally friendly, socially responsible, and economically viable.

Core Principles of Sustainable Design

Sustainable engineering design practices are built on three primary pillars: environmental, social, and economic sustainability. The environmental aspect focuses on reducing resource consumption, minimizing waste, and lowering emissions throughout the product lifecycle. Social sustainability ensures that engineering solutions contribute positively to communities and society at large, prioritizing safety, accessibility, and ethical production. Lastly, economic sustainability emphasizes designing products that are cost-effective, durable, and economically viable over their entire lifecycle, including production, operation, and disposal.

Lifecycle Thinking in Sustainable Design

A crucial aspect of sustainable engineering is adopting a lifecycle perspective. This approach involves considering the environmental and social impacts of a product from raw material extraction, through manufacturing, use, and disposal. Engineers are increasingly using tools like Life Cycle Assessment (LCA) to evaluate these impacts and optimize designs accordingly. By identifying areas where energy consumption, emissions, or waste can be reduced, engineers can make informed decisions that enhance sustainability.

For example, using materials that are renewable, recyclable, or biodegradable can significantly reduce environmental footprints. Similarly, designing for ease of disassembly and recycling at the end of a product’s life can prevent valuable materials from ending up in landfills.

Energy Efficiency and Material Optimization

Energy efficiency is a key component of sustainable design. This applies not only to the energy a product consumes during its use but also to the energy required for its manufacturing and disposal. By incorporating energy-efficient components and technologies, engineers can reduce the overall energy demand of a product. Lightweighting, or reducing the amount of material used in a design without compromising strength or performance, is another important strategy for improving sustainability. Lighter products often require less energy to manufacture and transport, resulting in lower emissions and operational costs.

Material selection plays a significant role in energy efficiency and sustainability. Engineers are now prioritizing materials with low environmental impacts, such as composites, recycled metals, and eco-friendly polymers. Innovative material technologies, like carbon-neutral concrete or bio-based plastics, are gaining traction as viable alternatives to conventional materials.

Circular Economy and Sustainable Engineering

Sustainable design aligns with the principles of the circular economy, which emphasizes keeping products, materials, and resources in use for as long as possible. This approach contrasts with the traditional linear economy, where products are made, used, and discarded. In the circular economy, engineers design products with longevity, reparability, and reusability in mind, allowing components or materials to be repurposed at the end of their lifecycle. This shift from a “take-make-dispose” model to a regenerative system helps conserve resources and reduce waste.

Innovations Driving Sustainable Design

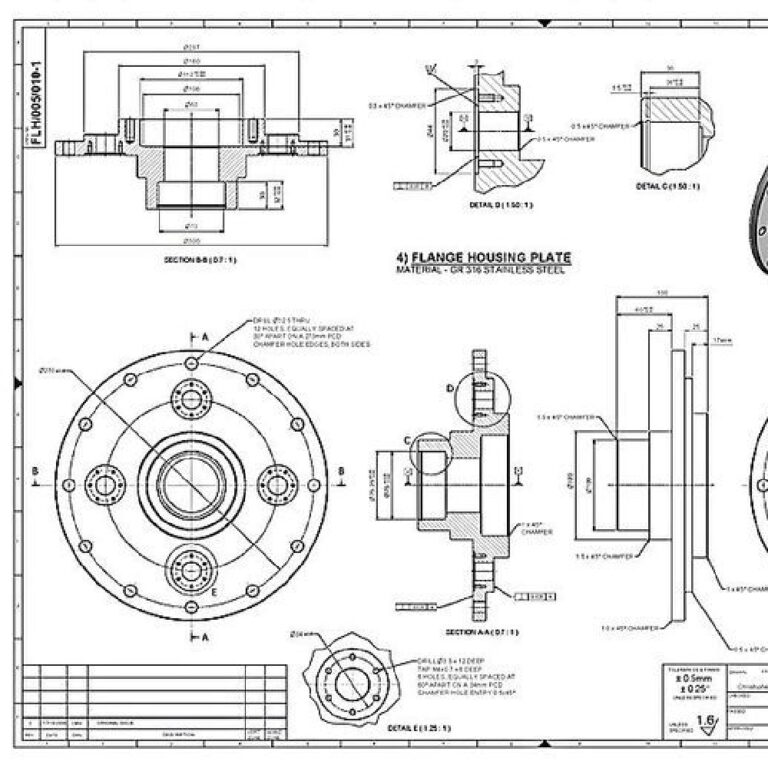

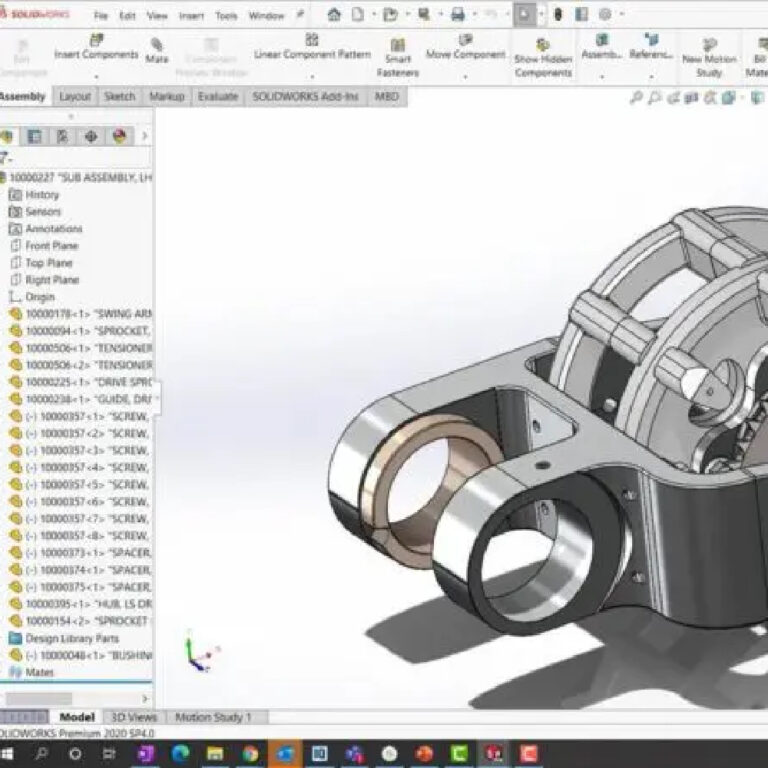

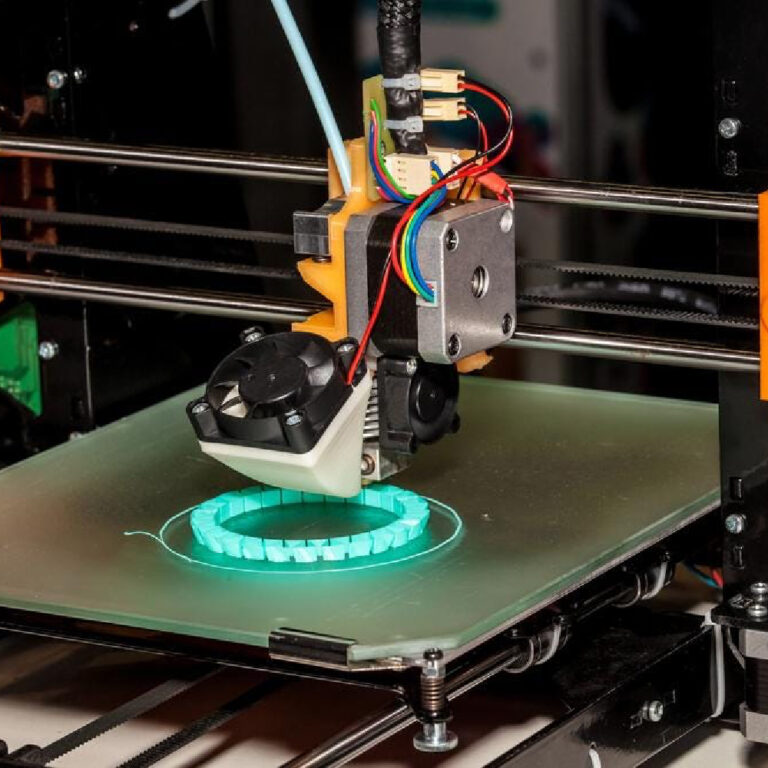

Technological innovations, such as 3D printing, artificial intelligence, and advanced simulation tools, are playing a pivotal role in advancing sustainable engineering design. For instance, 3D printing enables rapid prototyping with minimal material waste and allows for more complex and efficient designs that would be challenging to produce using traditional manufacturing methods. AI and simulation tools help engineers optimize designs for performance, efficiency, and sustainability before any physical prototypes are built, reducing resource consumption and costs.

Conclusion

Sustainable engineering design practices are reshaping the way products are conceived, manufactured, and used. By focusing on minimizing environmental impact, enhancing resource efficiency, and embracing innovations like lifecycle thinking and the circular economy, engineers can create products that meet the demands of today while safeguarding the future of our planet.