Introduction to Economic Considerations

Introduction to Economic Considerations in Custom Forging

Economic Considerations in Custom Forging play a pivotal role in the manufacturing industry, where the process offers unique advantages such as enhanced mechanical properties and designs tailored to meet specific customer requirements. Understanding these considerations is crucial for businesses aiming to optimize production processes, manage budgets effectively, and maximize returns on investment. This introduction delves into the key economic factors shaping the custom forging landscape, equipping stakeholders with the insights needed to make informed decisions.

At its core, the economic considerations in custom forging begin with understanding the cost structure involved in the process. Costs can vary significantly based on several factors, including the complexity of the part being forged, the materials used, and the scale of production. For example, intricate designs often require advanced tooling and longer production times, leading to increased costs. Similarly, the choice of materials can greatly affect pricing; high-performance alloys or specialty metals may come with premium price tags. By breaking down these costs, companies can gain insights into areas where they can optimize their budgets, potentially leading to significant savings.

Another critical aspect of economic considerations in custom forging is the return on investment (ROI). Investing in custom forged parts can yield substantial financial benefits when done correctly. Custom forgings typically offer enhanced durability, improved performance, and reduced weight compared to traditional manufacturing methods. These factors can translate into lower maintenance costs and longer product lifespans, ultimately contributing to a higher ROI. Companies must evaluate these benefits against the initial investment to determine whether custom forging is a financially sound decision.

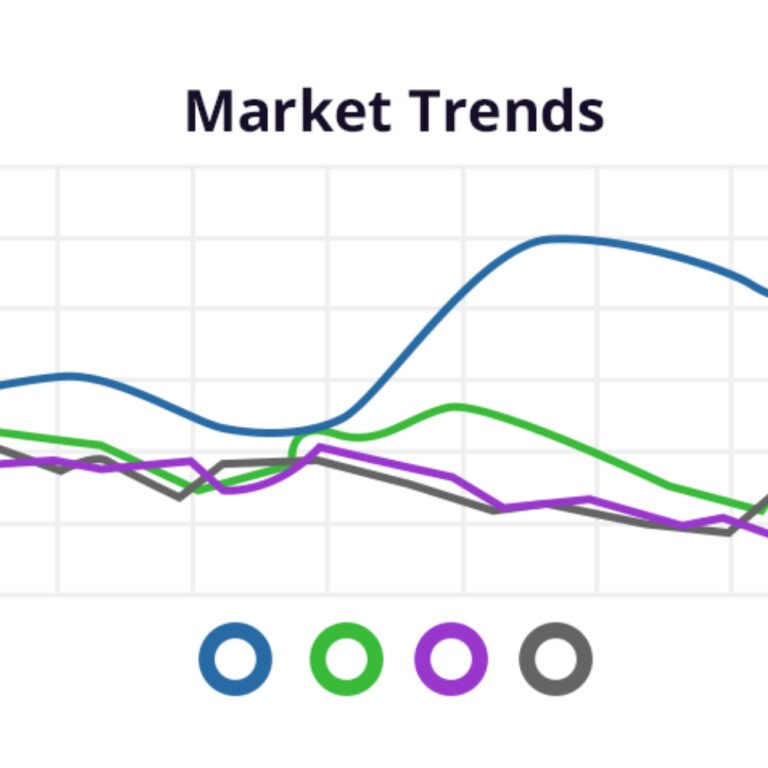

Market trends also play a crucial role in shaping the economic landscape of custom forging. Understanding current market conditions, including demand fluctuations, competitive pricing, and emerging technologies, can help businesses adjust their strategies accordingly. For instance, the rising demand for lightweight components in industries such as aerospace and automotive has led to increased interest in custom forging as a viable manufacturing method. Companies that stay ahead of market trends can position themselves competitively and capitalize on new opportunities for growth.

Additionally, pricing strategies for custom forged components are a significant consideration. Businesses must navigate a delicate balance between ensuring profitability and remaining competitive in the market. Developing pricing strategies that reflect the true value of custom forgings, considering both production costs and market demand, is essential for sustaining long-term profitability. This may involve exploring different pricing models, such as value-based pricing or tiered pricing based on order volumes, to maximize revenue potential while providing value to customers.

Supply chain management is another area where economic considerations come into play. The procurement of raw materials, logistics, and distribution can all impact the overall cost of custom forging. Efficient supply chain management practices can help minimize costs, improve lead times, and enhance customer satisfaction. Companies must continuously evaluate their supply chain strategies to identify areas for improvement and cost reduction.

In conclusion, economic considerations in custom forging encompass a wide range of factors, including cost structures, return on investment, market trends, pricing strategies, and supply chain management. By carefully analyzing these elements, businesses can make informed decisions that enhance their competitiveness and drive growth. Understanding these economic factors is essential for any organization looking to leverage the advantages of custom forging while ensuring financial viability and sustainability in their operations.