Innovative Solution for Marine Sector

Innovative Solution: A Case Study on Customized Forging for the Marine Sector

The marine sector presents unique challenges and opportunities for manufacturers, particularly in the realm of customized forging. The demands of this industry include the need for durable, corrosion-resistant components capable of withstanding harsh marine environments. At Manan Forge, we recently embarked on an innovative solution for marine sector that exemplified our ability to deliver customized, high-quality components tailored specifically for marine applications.

Project Overview

Our collaboration began with a leading marine equipment manufacturer that required a series of custom forged components for a new line of high-performance vessels. These components included various brackets, mounting fixtures, and specialized fittings, all of which needed to meet stringent industry standards for strength and reliability. The client faced challenges with their previous suppliers, particularly regarding lead times and the ability to produce parts with precise specifications.

Understanding Client Needs

To kick off the project, we engaged in thorough discussions with the client to fully understand their requirements. Key factors included the materials to be used, the specific properties desired for each component, and the environmental conditions they would face at sea. Our team conducted a comprehensive analysis of the expected loads, corrosion risks, and fatigue factors, which guided our design and manufacturing processes.

Custom Forging Solutions

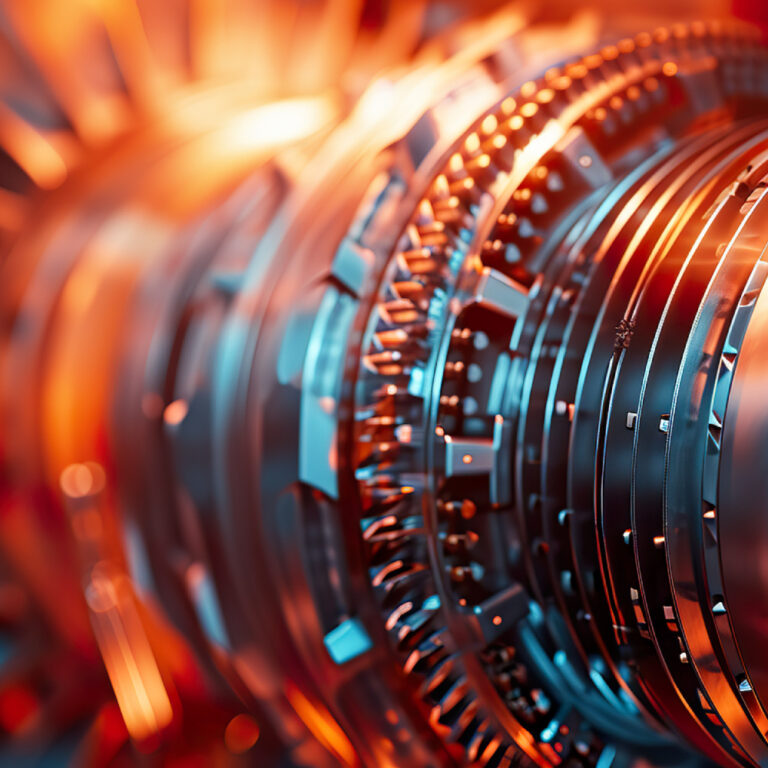

Using advanced forging techniques, we proposed the use of high-strength stainless steel alloys, which offer superior corrosion resistance while maintaining the structural integrity required for marine applications. Our engineering team developed a series of prototypes to validate the designs before proceeding to full-scale production. This iterative process allowed us to refine the specifications and ensure that each component would meet the client’s performance standards.

In addition to material selection, we implemented innovative forging methods to enhance the durability of the components. By employing precision forging techniques, we were able to produce parts with superior mechanical properties compared to traditional methods. This not only improved the performance of the components but also reduced the overall weight, a critical factor for marine vessels seeking efficiency and speed.

Quality Assurance and Testing

Quality assurance was paramount throughout the project. We conducted rigorous testing at various stages of production to ensure each component adhered to international marine standards. This included tensile testing, fatigue testing, and corrosion resistance evaluations. Our ISO certification ensured that our processes met the highest standards of quality control, providing the client with peace of mind.

Successful Outcomes

Upon completion, the forged components were delivered ahead of schedule, much to the client’s satisfaction. The high-performance vessels equipped with our customized parts entered the market successfully, receiving positive feedback for their reliability and efficiency. The client reported reduced maintenance costs and increased operational performance, solidifying our partnership for future projects.

This case study not only highlights our capabilities in customized forging for the marine sector but also illustrates our commitment to innovation and quality. By understanding client needs, leveraging advanced manufacturing techniques, and maintaining stringent quality controls, we were able to deliver solutions that not only met but exceeded expectations.

Conclusion

The success of this project underscores the importance of collaboration and innovation in the manufacturing process. At Manan Forge, we continue to strive for excellence in customized forging solutions, positioning ourselves as a trusted partner for clients in the marine industry and beyond. As we look to the future, we remain committed to addressing the evolving challenges of the industry with innovative, reliable, and high-quality products.